A maximum stock level is the upper limit of stock that should not be exceeded under normal circumstances without the prior agreement of the management. The aim of setting a maximum stock level is to avoid undue investment of capital leading to loss of interest, obsolescence of materials, and additional overheads in the form of higher rents. The main factors to consider when fixing the maximum stock level are: The maximum stock level can be calculated by applying the following formula: Another formula for the maximum stock level is given as follows: ZEE is a product manufactured from three raw materials: M, N, and Q. Each unit of ZEE requires 10 kg, 8 kg, and 6 kg of M, N, and Q respectively. The reorder levels of M and N are 15,000 kg and 10,000 kg, respectively. The minimum reorder level of Q is 25,000 kg. The weekly production of ZEE varies from 300 to 500 units, while the weekly average production is 400 units. Required: Calculate the following: The following additional data are given: 20,000 1. Minimum Stock Level of M = Reorder level - (Normal consumption per week x Average time required to obtain supplies) = 15,000 kgs. - (400 units x 10 kgs. x 3 weeks) = 15,000 - 12,000 = 3,000 kgs. 2. Maximum Stock Level of N = Reorder level + Reorder quantity - (Minimum consumption per week x Minimum time required to obtain supplies) = 10,000 kg + 15,000 kg - (300 units x 8 kg x 4 weeks) = 25,000 kg - 9,600 kg = 15,400 kg 3. Reorder level of Q = Maximum consumption per week x Maximum time required to obtain supplies = 500 units x 6 kg x 5 weeks = 15,000 kgMaximum Stock Level: Definition and Explanation

Main Factors Involved in Fixing the Maximum Stock Level

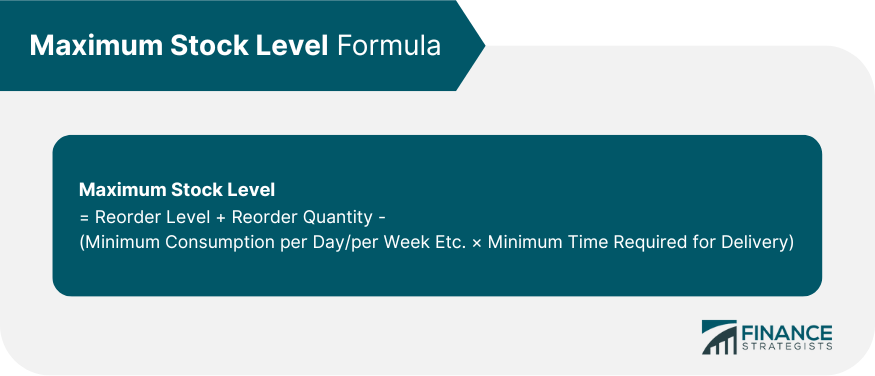

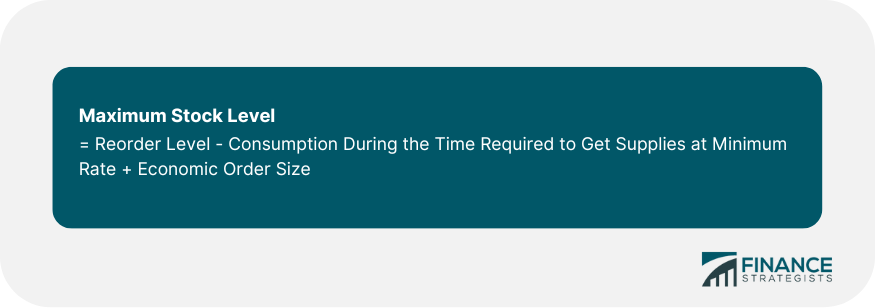

Formula for Maximum Stock Level

Example

M

N

Q

Reorder Quantity (kg)

15,000

20,000

Delivery (weeks):

Minimum

2

4

3

Average

3

5

4

Maximum

4

6

5

Solution

Maximum Stock Level FAQs

A maximum stock level is the upper limit of stock that should not be exceeded under normal circumstances without the prior agreement of the management.

The aim of setting a maximum stock level is to avoid the undue investment of capital leading to loss of interest, obsolescence of materials, and additional overheads in the form of higher rents.

Maximum stock level = reorder level + reorder quantity – (minimum consumption per day/per week etc. X minimum time required for delivery)

These are average rate of consumption of materials, time needed to obtain new supplies, amount of obsolescence available, availability of storage space economic order quantity, cost of carrying inventory or cost of storage, risk of deterioration in quality and obsolescence of materials, seasonal considerations in terms of price and availability of materials, incidence of insurance costs, which may be important for costly materials, inherent risks associated with materials and any restrictions imposed by the government in this regard

Some of the risks associated with having excessive inventory levels include obsolescence, deterioration in quality, and storage costs. Additionally, holding too much inventory can tie up working capital that could be used for other purposes, such as investing in new product development or marketing campaigns. Finally, large inventory levels may signal to customers that a company is struggling financially, which could lead to decreased sales.

True Tamplin is a published author, public speaker, CEO of UpDigital, and founder of Finance Strategists.

True is a Certified Educator in Personal Finance (CEPF®), author of The Handy Financial Ratios Guide, a member of the Society for Advancing Business Editing and Writing, contributes to his financial education site, Finance Strategists, and has spoken to various financial communities such as the CFA Institute, as well as university students like his Alma mater, Biola University, where he received a bachelor of science in business and data analytics.

To learn more about True, visit his personal website or view his author profiles on Amazon, Nasdaq and Forbes.