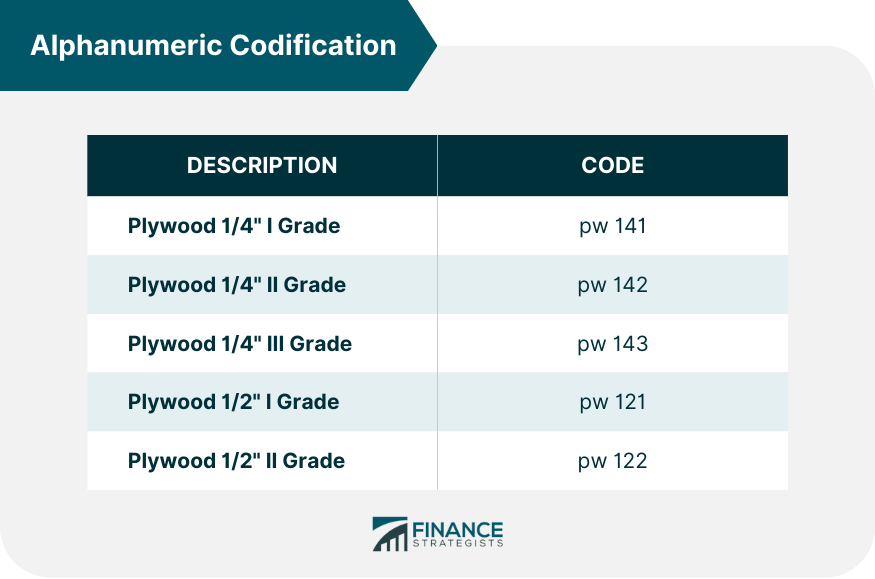

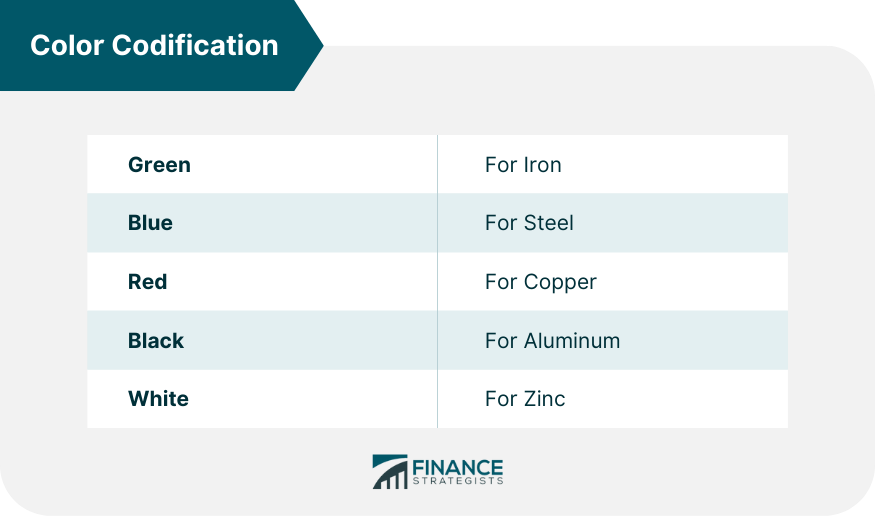

There are several common methods used to codify materials. These methods include alphabetical, mnemonic, numerical, decimal, alphanumeric, and color codification. As the name indicates, this method involves the use of alphabetical letters as codes to facilitate the easy and quick identification of materials. This is a modified version of the alphabetical codification system. It involves the use of alphabetical letters to create codes that aid memory. However, if similar codes are assigned to several items, this can lead to confusion, and the method also lacks flexibility. Also known as straight number codification, numbers are used in numerical codification to represent different items in a store. A series of numbers may be assigned to store items of similar nature. This is another numerical system of codification with the difference that instead of full numbers, decimals are used. It is generally used in businesses where a mechanized system of accounting is in use. Under this method, whole numbers are used to indicate the main group or the master group, while decimals are used to indicate sub-groups. However, the main disadvantage of decimal codification is its complexity. It also involves the possibility of misplacing or omitting decimals. Also known as the alpheno-serial system or the combined code system, this system uses alphabetical letters in conjunction with numbers to codify store items. The broader groups of store items are represented by alphabetical symbols while the detailed groups are represented by numbers. As the name indicates, under this method, color markings are used to denote code numbers. This method can be applied to codify metals, cables, small component parts, drums of oil, and various other items. If the colors used are not too complicated, this method affords a ready means of identification on sight. For example, in the case of metal, color codes can be used as follows: Several principles should be kept in mind when assigning codes. First, the codes should be easy to understand, enabling the storekeeping staff to use them conveniently. There should also be no duplication across codes, and each code should relate to only one type of store. The code number should be elastic, allowing new items to be added to the store easily and logically. Codes must also identify the material without ambiguity or uncertainty. Ideally, codes should be as short as possible because large codes will lead to errors. Lastly, mnemonic codes are both easier to remember and associated with a reduced likelihood of errors. The main advantages of codifying materials are stated as follows: 1. Avoidance of Lengthy Description: Codification helps in avoiding the use of lengthy names and descriptions for store items, thus saving time and energy. 2. Accurate Identification of Stores: Codification assists in the accurate and convenient identification of store items. Easy identification of store items saves time and costs involved in-store handling. 3. Convenience in Issue of Materials: Codification of store items on scientific lines helps in eliminating the possibility of errors in the issue of materials. It also increases the efficiency of store-keeping staff. 4. Maintenance of Secrecy: Every manufacturing concern, owing to necessity, attempts to keep its production activities and processes a secret. Codification of store items helps in maintaining secrecy in production activities. 5. Simplification of Stores Accounting: Codification of store items helps in maintaining accurate records since scientific codification enables systematicity. 6. Prevention of Duplication: Codification prevents the duplication of items. As all similar items in the store are grouped together, when an item is coded once, it is not assigned an alternative name. 7. Convenience in Preparing Material Forms: Codification of store items makes the preparation of various forms and documents relating to stores easy and convenient (e.g., Bill of Materials, Purchase Requisitions, and Material Requisitions). 8. Other Advantages: Codification helps in the standardization of store items and in the reduction in their variety. It also helps in reducing storage costs and increasing efficiency.Methods of Codification

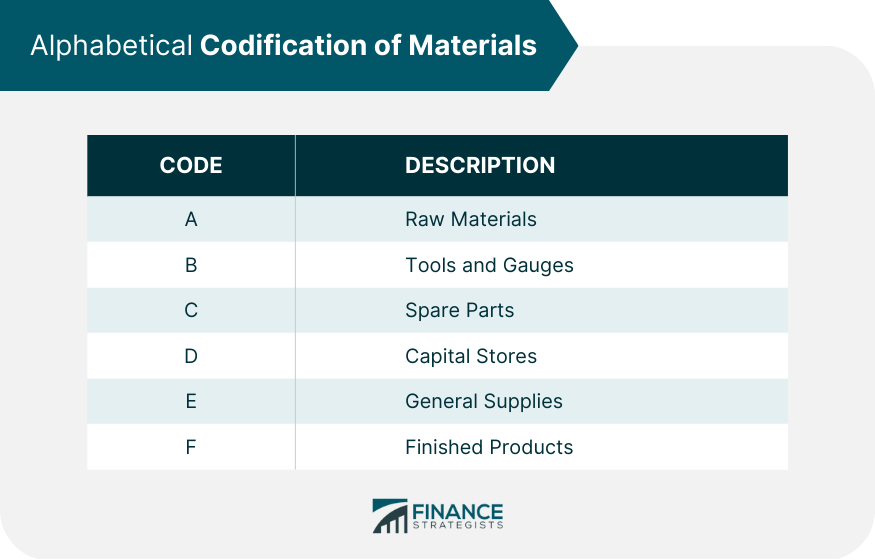

Alphabetical Codification of Materials

Alphabetical codification of materials is the most simple approach, but it lacks flexibility.Mnemonic Codification

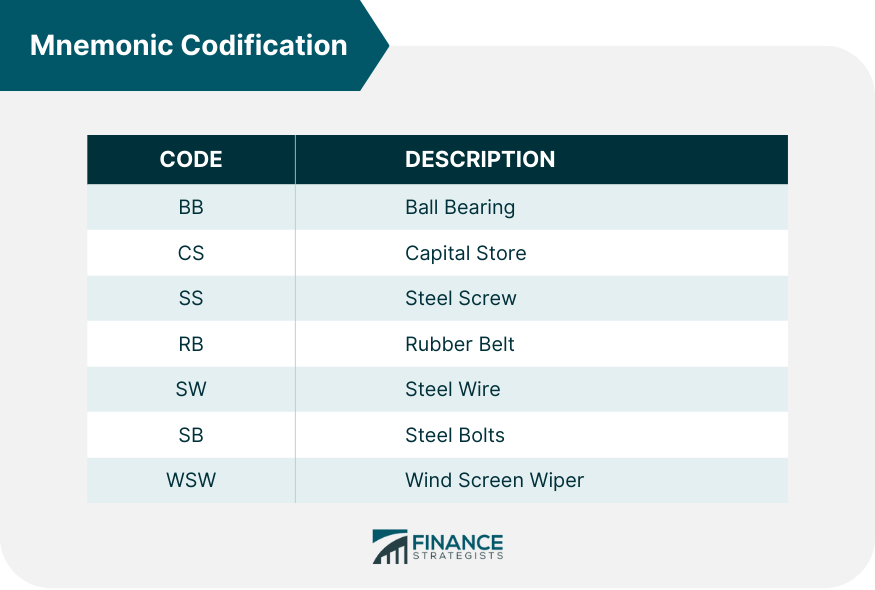

Mnemonic codification is simple to operate because it helps staff to memorize the items in a store. Numerical Codification

Numerical codification of materials is the simplest and most widely used method in manufacturing enterprises due to its flexibility.Decimal Codification

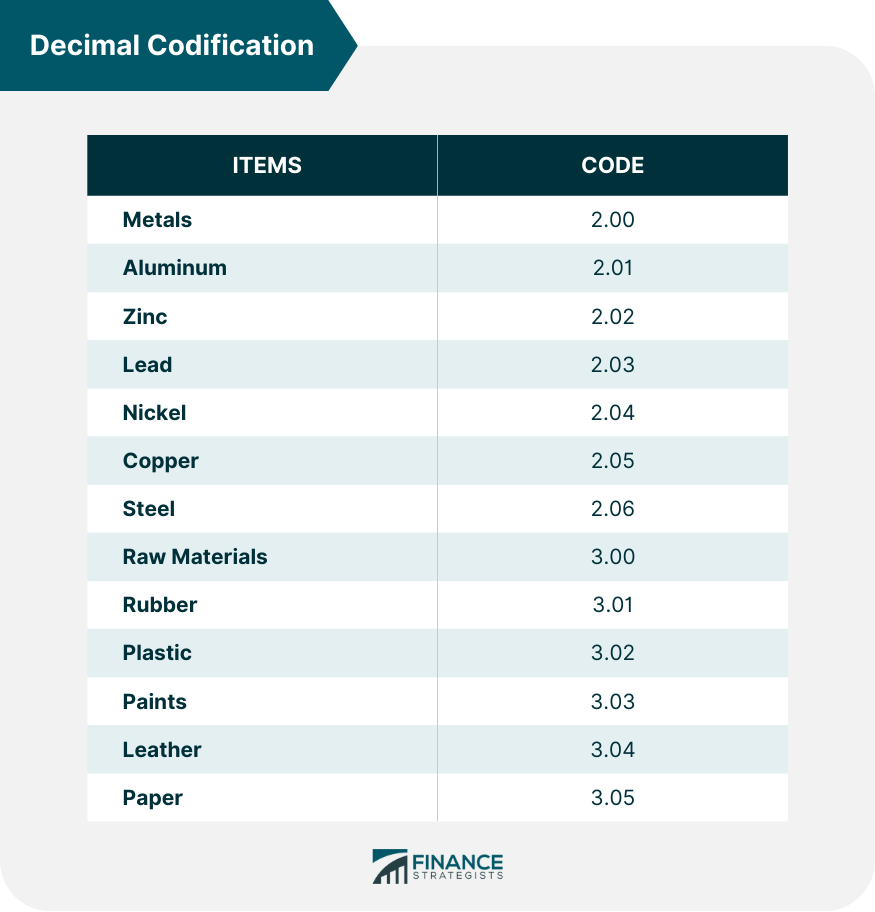

This method has the advantage of flexibility and unlimited scalability. Also, using decimal points makes the numbers easier to read and remember.Alphanumeric Codification

Color Codification

This method is simple but lacks flexibility. That is to say, when the number of store items increases, it is not possible to expand the number of colors.Principles of Codification of Materials

Advantages of Codification of Materials

Methods and Principles of Codification of Materials FAQs

There are several common methods used to codify materials. These methods include alphabetical, mnemonic, numerical, decimal, alphanumeric, and color codification.

As the name indicates, this method involves the use of alphabetical letters as codes to facilitate the easy and quick identification of materials.

This is a modified version of the alphabetical codification system. It involves the use of alphabetical letters to create codes that aid memory.

Also known as straight number codification, numbers are used in numerical codification to represent different items in a store. A series of numbers may be assigned to store items of similar nature.

This is another numerical system of codification with the difference that instead of full numbers, decimals are used it is generally used in businesses where a mechanized system of accounting is in use. Under this method, whole numbers are used to indicate the main group or the master group, while decimals are used to indicate sub-groups.

True Tamplin is a published author, public speaker, CEO of UpDigital, and founder of Finance Strategists.

True is a Certified Educator in Personal Finance (CEPF®), author of The Handy Financial Ratios Guide, a member of the Society for Advancing Business Editing and Writing, contributes to his financial education site, Finance Strategists, and has spoken to various financial communities such as the CFA Institute, as well as university students like his Alma mater, Biola University, where he received a bachelor of science in business and data analytics.

To learn more about True, visit his personal website or view his author profiles on Amazon, Nasdaq and Forbes.