The 416(g) Test is a standardized procedure designed to evaluate the safety, quality, and performance of products and materials within various industries. The test is essential for ensuring that products adhere to industry standards and regulatory requirements. The primary objective of the 416(g) Test is to ensure that products meet the necessary specifications for their intended use. This helps maintain consumer safety, protect the environment, and guarantee the overall quality of products. The 416(g) Test is used across a wide range of industries, including manufacturing, pharmaceuticals, food and beverages, and consumer goods. The 416(g) Test was developed as a response to the growing need for standardized testing methods to evaluate products and materials across various sectors. Over time, the test has evolved to address emerging issues and trends in product safety and quality. The 416(g) Test has been shaped by various regulatory bodies and legislative actions, ensuring that the test remains relevant and effective in maintaining safety and quality standards. As industry needs and regulatory requirements have changed, the 416(g) Test has undergone updates and modifications to maintain its relevance and effectiveness in evaluating products and materials. The 416(g) Test encompasses a broad range of parameters, including physical, chemical, and performance-related properties, to ensure a comprehensive evaluation of products and materials. The 416(g) Test utilizes specialized equipment and tools designed to accurately measure and evaluate the various test parameters. These tools can include testing machines, measuring instruments, and analytical equipment. The 416(g) Test follows a systematic approach to ensure accurate and consistent results. This involves preparing the test samples, conducting the test using appropriate equipment and tools, and documenting the results for analysis. Interpreting the results of the 416(g) Test involves comparing the data to established specifications and industry standards to determine whether a product meets the necessary criteria for safety, quality, and performance. Various factors can influence the results of the 416(g) Test, including sample preparation, equipment calibration, and environmental conditions. These factors must be carefully controlled to ensure accurate and reliable test results. Accurate testing is essential for maintaining safety and quality standards, as it enables manufacturers and regulatory authorities to identify and address potential issues before they become more significant problems. In manufacturing, the 416(g) Test is crucial for evaluating the safety, quality, and performance of materials and products, ensuring that they meet industry standards and regulatory requirements. The 416(g) Test plays a vital role in the pharmaceutical industry, where it is used to evaluate the safety, efficacy, and quality of drugs and medical devices. In the food and beverage industry, the 416(g) Test helps ensure the safety and quality of products by evaluating factors such as chemical composition, nutritional content, and shelf life. To ensure compliance with the 416(g) Test standards, manufacturers and organizations must adhere to established regulatory requirements and guidelines. These may include industry-specific regulations, national and international standards, and best practices. Organizations can follow various best practices to ensure compliance with the 416(g) Test standards, such as implementing quality management systems, training staff on proper testing procedures, and routinely auditing and calibrating testing equipment. Non-compliance with the 416(g) Test standards can result in serious consequences, including product recalls, fines, damage to brand reputation, and potential harm to consumers or the environment. In recent years, there have been significant advancements in testing technology that can improve the accuracy and reliability of the 416(g) Test. One such development is the introduction of automated testing systems. These systems utilize robotics and software to perform testing procedures, which reduces the risk of human error and increases the precision of results. Automated testing systems can also provide faster turnaround times, allowing manufacturers to bring products to market more quickly. Another development in 416(g) testing is the use of non-destructive testing methods. These methods can detect defects or flaws in products without damaging them, allowing for more comprehensive testing and analysis. Non-destructive testing methods include ultrasonic testing, radiography, and magnetic particle inspection. Advancements in software and data analysis have also improved the interpretation of 416(g) test results. The software can now automatically analyze large datasets, identify trends, and provide insights into potential issues or areas for improvement. This technology can help manufacturers make data-driven decisions, improve quality control, and reduce the risk of product failures. The 416(g) Test is an essential tool for evaluating the safety, quality, and performance of products and materials within various industries. By following standardized procedures and adhering to regulatory requirements, organizations can ensure that their products meet the necessary specifications for their intended use. The 416(g) Test plays a crucial role in maintaining safety and quality standards, as it enables manufacturers and regulatory authorities to identify and address potential issues before they become more significant problems. As industries evolve and new products and materials are developed, the need for effective testing and compliance will continue to grow. The 416(g) Test will remain a critical tool for ensuring product safety and quality, helping to protect consumers and the environment.Overview of 416(g) Test

Background and History of the 416(g) Test

Development of the Test

Regulatory and Legislative History

Evolution and Updates Over Time

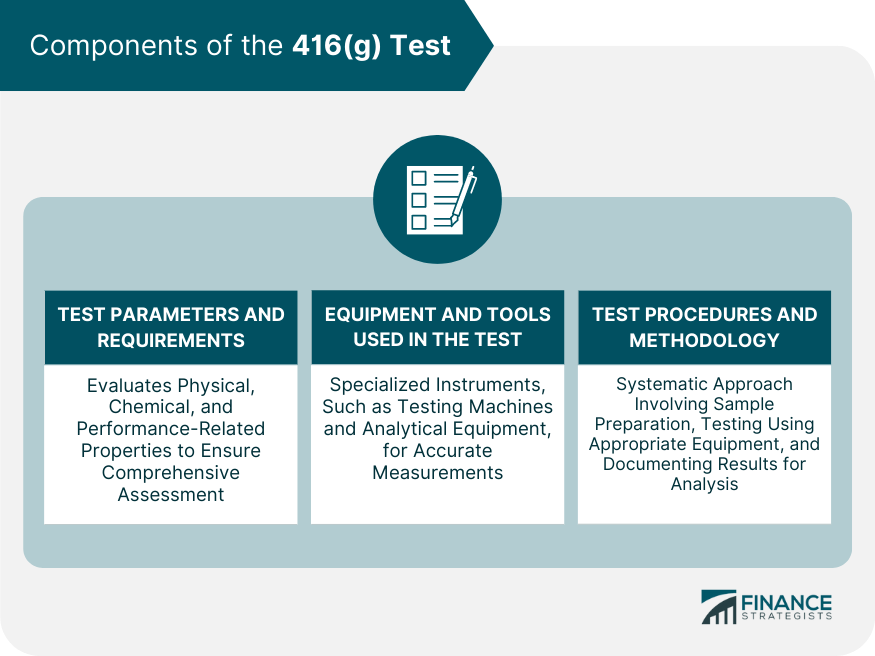

Components of the 416(g) Test

Test Parameters and Requirements

Equipment and Tools Used in the Test

Test Procedures and Methodology

Interpretation of 416(g) Test Results

Understanding Test Results

Factors That May Influence Results

Importance of Accurate Testing

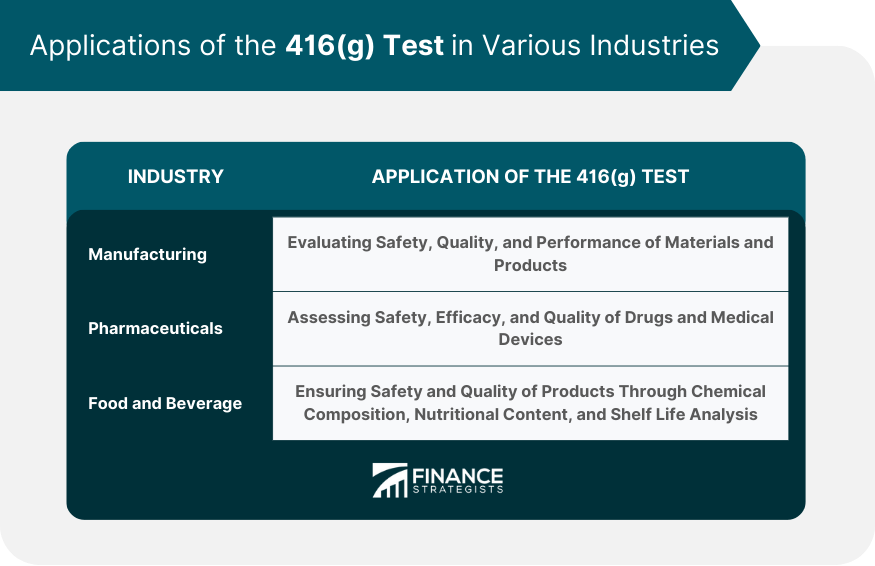

Applications of the 416(g) Test in Various Industries

Manufacturing Industry

Pharmaceutical Sector

Food and Beverage Industry

Compliance With 416(g) Test Standards

Regulatory Requirements and Guidelines

Best Practices for Ensuring Compliance

Consequences of Non-Compliance

Recent Developments in 416(g) Testing

Automated Testing Systems

Non-destructive Testing Methods

Software Advancements and Data Analysis

Final Thoughts

416(g) Test FAQs

The primary purpose of the 416(g) Test is to evaluate the safety, quality, and performance of products and materials within various industries, ensuring that they adhere to industry standards and regulatory requirements.

The 416(g) Test is commonly used across a wide range of industries, including manufacturing, pharmaceuticals, food and beverages, and consumer goods, to maintain product safety and quality.

Organizations can ensure compliance with the 416(g) Test standards by adhering to established regulatory requirements and guidelines, implementing quality management systems, training staff on proper testing procedures, and routinely auditing and calibrating testing equipment.

Factors that may influence the results of the 416(g) Test include sample preparation, equipment calibration, and environmental conditions. These factors must be carefully controlled to ensure accurate and reliable test results.

Technological advancements have the potential to impact the future of the 416(g) Test by improving the accuracy, efficiency, and scope of testing processes. Innovations in testing technology can help further enhance product safety and quality, and adapt to new industry trends and regulatory requirements.

True Tamplin is a published author, public speaker, CEO of UpDigital, and founder of Finance Strategists.

True is a Certified Educator in Personal Finance (CEPF®), author of The Handy Financial Ratios Guide, a member of the Society for Advancing Business Editing and Writing, contributes to his financial education site, Finance Strategists, and has spoken to various financial communities such as the CFA Institute, as well as university students like his Alma mater, Biola University, where he received a bachelor of science in business and data analytics.

To learn more about True, visit his personal website or view his author profiles on Amazon, Nasdaq and Forbes.