Material Requirements Planning (MRP) is a computer-based inventory management and production planning system that helps manufacturers optimize their supply chain processes. It ensures the availability of materials, components, and products to meet customer demand while minimizing inventory costs and production delays. MRP aims to streamline the manufacturing process by coordinating production schedules, material purchasing, and inventory management. The primary benefits include improved production efficiency, reduced lead times, better inventory control, and more accurate forecasting of material needs. The concept of MRP emerged in the 1960s as a response to the increasing complexity of manufacturing operations. With advancements in computer technology, MRP systems evolved over time, becoming more sophisticated and capable of addressing a wider range of production and inventory management challenges. The Master Production Schedule is a plan that outlines the anticipated production of finished goods over a specific period. It serves as the foundation for MRP calculations, determining the timing and quantities of material requirements for each manufacturing stage. The Bill of Materials is a comprehensive list of all raw materials, components, and sub-assemblies needed to produce a finished product. It provides a hierarchical structure that shows the relationship between different items and their quantities, enabling accurate material planning and procurement. Accurate inventory records are crucial for MRP systems, as they track the quantities of raw materials, work-in-progress items, and finished products. These records inform the MRP system of the current stock levels and help identify any potential shortages or surpluses that may arise during the production process. The planning horizon is the time frame in which an MRP system operates to fulfill production and inventory management objectives. It typically ranges from a few weeks to several months, depending on the complexity and lead times of the manufacturing process. Lead times represent the duration between placing an order for materials or components and receiving them for production. Accurate lead time estimates are essential for MRP systems to schedule production and purchasing activities effectively, preventing delays and stockouts. The MRP process is a series of sequential steps that convert the Master Production Schedule and Bill of Materials into a detailed production and purchasing plan. It involves determining gross requirements, calculating net requirements, time-phased order point calculations, lot-sizing, order release, and updates and adjustments. Gross requirements refer to the total quantity of materials or components needed to fulfill the Master Production Schedule. These requirements are derived from the demand for finished goods and are used to calculate the net requirements for each item in the Bill of Materials. Net requirements represent the actual amount of materials or components required for production, taking into account current inventory levels and scheduled receipts. Net requirements are calculated by subtracting on-hand inventory and scheduled receipts from the gross requirements. TPOP is a technique used in MRP systems to determine when orders for materials or components should be placed. It takes into account the lead times and net requirements of each item, ensuring that orders are placed in a timely manner to meet production schedules without causing excess inventory. Lot-sizing involves determining the optimal order quantity for each item to minimize production, inventory, and ordering costs. Once the lot sizes are established, orders can be released to suppliers or internal production departments to fulfill the material requirements. MRP systems require regular updates and adjustments to reflect changes in production schedules, demand, inventory levels, and other factors. These updates ensure the accuracy and effectiveness of the MRP system, enabling manufacturers to adapt to changing conditions and maintain optimal inventory levels. MRP I, or Material Requirements Planning, is the original version of MRP that focuses on inventory control and material planning. It uses the MPS, BOM, and inventory data to generate production and purchasing schedules, helping manufacturers optimize their inventory management and production processes. MRP II, or Manufacturing Resource Planning, is an extension of MRP I that incorporates additional aspects of the manufacturing process, such as capacity planning, shop floor scheduling, and financial management. MRP II provides a more comprehensive approach to production planning, enabling better coordination and control of manufacturing resources. Closed-loop MRP refers to an MRP system that incorporates feedback mechanisms to continuously monitor and adjust production plans based on actual performance. This approach enables manufacturers to identify and address discrepancies between planned and actual production, resulting in improved accuracy and responsiveness to changing conditions. Distribution Requirements Planning is an extension of MRP that focuses on the distribution and logistics aspects of the supply chain. DRP manages the flow of finished goods from production facilities to distribution centers and customers, optimizing inventory levels and transportation costs across the entire supply chain. MRP systems help manufacturers maintain optimal inventory levels by accurately forecasting material requirements and coordinating production and purchasing activities. This leads to reduced carrying costs, minimized stockouts, and a more efficient use of warehouse space. By providing a detailed production plan, MRP systems enable manufacturers to optimize the use of resources, reduce setup times, and minimize production delays. This results in increased productivity, reduced lead times, and a more efficient manufacturing process. MRP systems facilitate better communication and coordination between manufacturers and suppliers, ensuring that materials are purchased and delivered in a timely manner. This helps prevent production delays and stockouts while also enabling manufacturers to take advantage of volume discounts and favorable payment terms. MRP systems provide manufacturers with insights into capacity requirements, enabling better allocation of resources and more accurate scheduling of production activities. This helps to prevent overloading or underutilizing production facilities, leading to increased efficiency and cost savings. By accurately forecasting material requirements and optimizing production schedules, MRP systems help manufacturers minimize the occurrence of stockouts and excess inventory. This leads to improved customer satisfaction, reduced carrying costs, and a more efficient supply chain. MRP systems rely on accurate and up-to-date data to generate effective production and purchasing plans. Inaccurate or outdated data can lead to incorrect material requirements, resulting in production delays, stockouts, or excess inventory. MRP systems can be complex and require significant effort to implement and maintain. This complexity can present challenges for manufacturers, particularly smaller organizations with limited resources or expertise in MRP systems. Lead times for materials and components can vary due to factors such as supplier performance, transportation delays, or changes in demand. MRP systems may struggle to adapt to these fluctuations, potentially leading to production delays or inventory imbalances. MRP systems may not effectively adapt to sudden or significant changes in demand patterns, such as seasonal fluctuations or new product introductions. This can result in inaccurate production plans and inventory levels, leading to stockouts or excess inventory. Implementing and maintaining an MRP system can be costly, particularly for small and medium-sized businesses. These costs include software and hardware investments, employee training, and ongoing system maintenance, which may present financial challenges for some organizations. Modern MRP systems are often integrated with other enterprise systems, such as Enterprise Resource Planning (ERP) and Supply Chain Management (SCM) systems. This integration enables more comprehensive and efficient management of manufacturing operations, leading to improved overall business performance. As Industry 4.0 continues to transform manufacturing through technologies such as IoT, big data, and automation, MRP systems are evolving to better support these advancements. By incorporating real-time data and advanced analytics, modern MRP systems can offer improved accuracy and adaptability in the face of changing manufacturing environments. Cloud-based MRP solutions offer increased flexibility, scalability, and cost-effectiveness compared to traditional on-premise systems. By leveraging the cloud, manufacturers can access their MRP systems from anywhere and easily scale resources to meet changing demands. The integration of artificial intelligence (AI) and machine learning technologies into MRP systems has the potential to significantly enhance their capabilities. These technologies can improve demand forecasting, optimize production schedules, and enable more adaptive and responsive inventory management. Material Requirements Planning (MRP) is a vital component of modern manufacturing, helping organizations optimize inventory management, production efficiency, and supply chain coordination. By leveraging key components such as MPS, BOM, and inventory records, MRP systems generate detailed production and purchasing plans that enable manufacturers to meet customer demand while minimizing costs and lead times. As manufacturing continues to evolve through advancements in technology and changing market demands, MRP systems will need to adapt to remain effective. Key trends shaping the future of MRP include increased integration with other enterprise systems, the incorporation of AI and machine learning technologies, and the adoption of cloud-based solutions. These developments have the potential to further enhance the benefits of MRP, enabling manufacturers to better navigate the complexities of modern manufacturing environments.What Is Material Requirements Planning (MRP)?

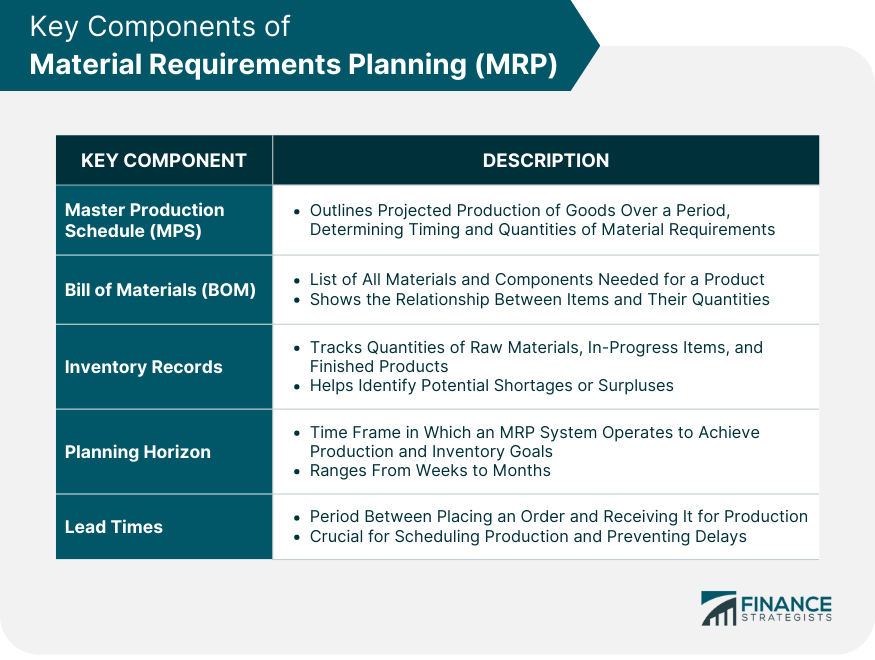

Key Components of MRP

Master Production Schedule (MPS)

Bill of Materials (BOM)

Inventory Records

Planning Horizon

Lead Times

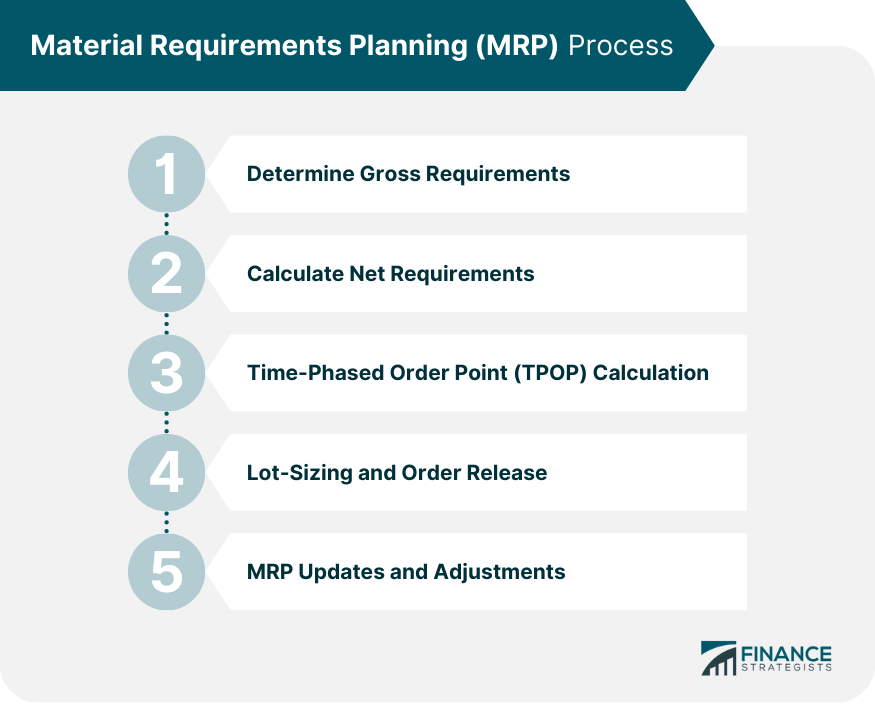

MRP Process

Step 1: Determine Gross Requirements

Step 2: Calculate Net Requirements

Step 3: Time-Phased Order Point (TPOP) Calculation

Step 4: Lot-Sizing and Order Release

Step 5: MRP Updates and Adjustments

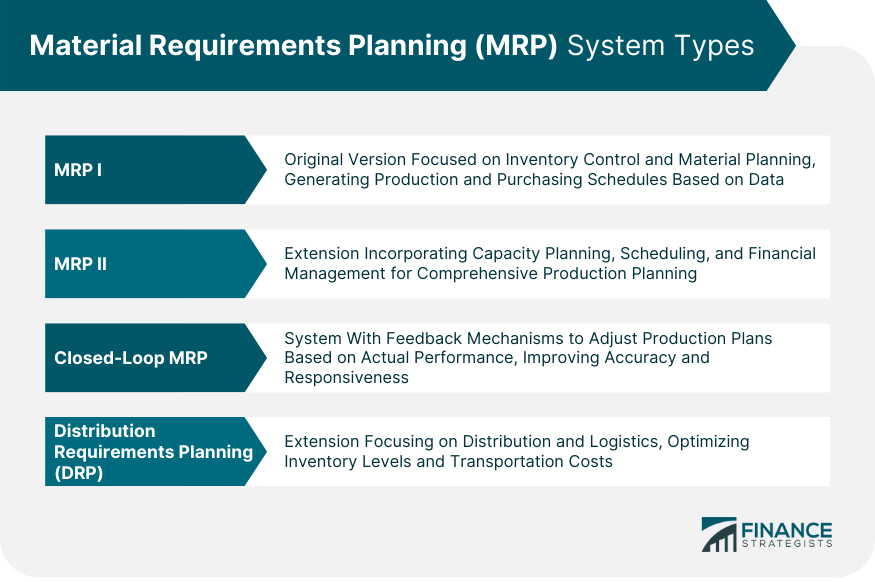

MRP System Types

MRP I

MRP II

Closed-Loop MRP

Distribution Requirements Planning (DRP)

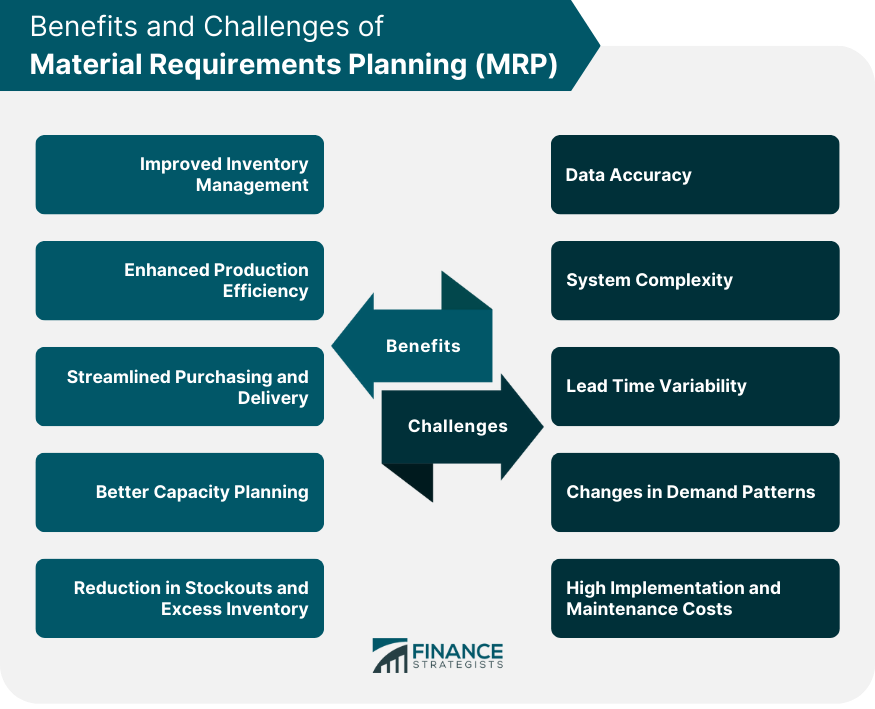

Benefits of MRP

Improved Inventory Management

Enhanced Production Efficiency

Streamlined Purchasing and Delivery

Better Capacity Planning

Reduction in Stockouts and Excess Inventory

Challenges and Limitations of MRP

Data Accuracy

System Complexity

Lead Time Variability

Changes in Demand Patterns

High Implementation and Maintenance Costs

MRP in the Modern Manufacturing Environment

Integration With Other Systems (ERP, SCM)

MRP and Industry 4.0

Cloud-Based MRP Solutions

Artificial Intelligence (AI) and Machine Learning in MRP

Final Thoughts

Material Requirements Planning (MRP) FAQs

Material Requirements Planning (MRP) is a computer-based inventory management and production planning system that helps manufacturers optimize their supply chain processes. The main benefits of MRP include improved inventory management, enhanced production efficiency, streamlined purchasing and delivery, better capacity planning, and reduced stockouts and excess inventory.

The key components of MRP are the Master Production Schedule (MPS), Bill of Materials (BOM), inventory records, planning horizon, and lead times. These components work together to generate detailed production and purchasing plans, enabling manufacturers to meet customer demand while minimizing costs and lead times.

MRP I focuses primarily on inventory control and material planning, while MRP II incorporates additional aspects of the manufacturing process, such as capacity planning, shop floor scheduling, and financial management. Closed-Loop MRP refers to an MRP system that includes feedback mechanisms to continuously monitor and adjust production plans based on actual performance, improving accuracy and responsiveness to changing conditions.

Some challenges and limitations of MRP systems include data accuracy, system complexity, lead time variability, changes in demand patterns, and high implementation and maintenance costs. Addressing these challenges is crucial for ensuring the effectiveness and efficiency of MRP systems in managing inventory and production processes.

MRP is evolving through integration with other enterprise systems (ERP, SCM), adoption of Industry 4.0 technologies, implementation of cloud-based MRP solutions, and the incorporation of artificial intelligence (AI) and machine learning. These developments enhance the capabilities of MRP systems, enabling manufacturers to better navigate the complexities of modern manufacturing environments.

True Tamplin is a published author, public speaker, CEO of UpDigital, and founder of Finance Strategists.

True is a Certified Educator in Personal Finance (CEPF®), author of The Handy Financial Ratios Guide, a member of the Society for Advancing Business Editing and Writing, contributes to his financial education site, Finance Strategists, and has spoken to various financial communities such as the CFA Institute, as well as university students like his Alma mater, Biola University, where he received a bachelor of science in business and data analytics.

To learn more about True, visit his personal website or view his author profiles on Amazon, Nasdaq and Forbes.